Copyright 2004 by Junior Doughty

Click thumbnails for full size photos

.

|

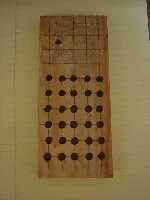

A while back I bought a perfectly good 30-30-specific loading block from Sinclair International (#PB06 = $7.75). It holds 50 rounds and although it works great for loading, it's not so great for shooting a couple of 5 shot groups from my cluttered shooting bench. So I decided to build a smaller one.

The horizontal holes are 3/4" apart, and the vertical holes are 1" apart. They're about 1" deep. I drilled them with the 1/2" bit you see on the right. As a 30-30 rim is .506" in diameter, the bit was slightly too small. Being a Frugal Outdoorsman, no way would I spend $15 for a bigger bit. So I figured a little reaming with the 1/2" rotary rasp you see would enlarge the holes. It did, but the cases wouldn't easily drop in the holes. Time for the thinking cap. Truthfully, while I pondered over the $15 bit I wouldn't buy and rasped some more with the rotary rasp, I discovered I couldn't blow all the rasped-out wood dust from the holes. So I decided to wash it out. Well, the block then soaked, the wood then swelled, and I could then get the cases in the holes only by force. So I rasped out the wet and swelled holes. Lo and behold, when the block dried the cases dropped easily into the holes. Genius, huh? As I had no room in the block to drill full size holes for fouling rounds, I centered the area between the rows and drilled three holes just slightly smaller than case neck O.D. Then I stuck the fouling shot cases in the block nose down. It works great because the fouling shot cases stay in the slightly-too-small holes even if I turn the block upside down. As my fouling shot cases are old R P cases and my for-group cases are new WW cases, there's very little chance they'll get mixed. The beaded thingy at the top right of the block is a muzzleloader nipple pick. It's for cleaning dust particles from a peep sight target aperture. The 30-30 block worked so well I decided to make one for 222 Rem. Since a 222 Rem case is shorter than a 30-30 case, I decided to use a 1 x 4. To simplify the job and to make perfectly flat spots for the case heads to rest upon, I decided to drill the holes all the way through the 1 x 4 and to glue a backing board to the 1 x 4.

I marked off the area at the top for removal in order to make a little tray for ear plugs, etc. The hole you see is for entry of a coping saw blade.

IMPORTANT: Use glue sparingly, especially near the holes. If a little oozes into a hole, it will make a lump, and the case will sit whopsided.

I included this photo so you could see the fit of the 1 x 4 to the 1/8" plywood.

The 222 Rem block also fits 223 Rem, including 223-based rounds such as 7mm TCU.

|