and Loading

Bullets cast over a campfire and sized & lubed & loaded beside the campfire

Click photos for full size versions.

|

The idea for this campfire bullet casting and loading article came when I found about 10 lbs of wheelweights in a pile of trash some a--hole dumped in the river bottom near my campsite. I decided to go camping and make bullets from those wheelweights. Then I'd load them beside the campfire and, hopefully, harvest a deer with one of them come hunting season. I guess it was my way of getting revenge on the a--hole.

The rifle I used then and now would be my Winchester Model 94 30-30 "Woods Rifle." Then, I used a Lee Classic Loader in 30-30, but I used a Lee Hand Press for crimping because I didn't like the Classic Loader's crimping method. However, that method works just fine I've since learned, so out of the bag came the Lee Hand Press and a 7/8x14 crimping die. Then, I used Lee 1.3 cc and .5 cc dippers to load 1.8 cc of H4198. Now, I used only one dipper—a Lee 1.7 cc dipper modified to hold 2.0 cc of surplus 4895. Then, I used Lee C309-170-F bullets cast and lubed at home. Now, I used a recently discontinued 2-hole Ranch Dog-designed and Lee-made TLC311-165-RF mold, and I cast the bullets beside the campfire. For sizing and gas check seating, I used a Lee .309" push-through sizing die operated in whack it mode atop a stump—beside the campfire of course. In the photo below taken a few days after the camping trip, we see the black bag and all the equipment it contained spread across the tailgate of my pickup. Missing is the zip sandwich bag I used for lubing the bullets with Lee Liquid Alox. And I forgot to include another zip sandwich bag containing 20 or so fired 30-30 cases.

Here's a look inside the Lee Classic Loader box. If you'll notice, there's several extra items in the box. The picture below shows those extra items.

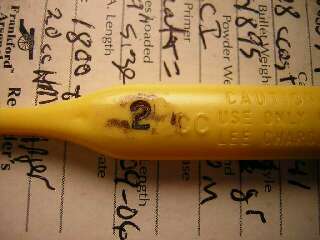

I also permanently labeled the dipper as you see here. Not doing so would be dangerous!

Here we see the a--hole's wheelweights in the little Lyman pot and on their way to becoming venison-making ammo. This is the same campfire location from the 2003 article. I'm using an adjustable rope I call my "Bean Rope," and it's hanging from the same limb as in 2003. If you'll notice, it doesn't take a big fire to cast bullets.

My bean rope looks like it's hanging at an angle, but that's due to an un-level camera and a cheap camera lens. I knocked the sprues off and onto the rusty old cooking grate, and I let the bullets fall on the towel between my feet. The Lyman dipper is inside the pot of molten lead on the campfire. The casting process was:

Except for the campfire smoke getting in my eyes, it was just as easy to cast bullets beside a campfire as it was on my casting bench at home.

Except for the campfire smoke getting in my eyes, it was just as easy to cast bullets beside a campfire as it was on my casting bench at home.Here's a closer view—which gives my bean rope an even greater angle. Below the wooden slider is a chain, to which the pot is hooked. Above the slider, the "rope" is an almost invisible nylon cord. In the full size version of this photo you can see the business end of the Lyman dipper down inside the molten lead where it stays hot and stays full. The handle end of the dipper rests on the cool end of a stick of firewood. The reader who wishes to repeat this campfire casting process would do well to remember that little detail—it kept the wooden dipper handle out of the fire and cool and readily available for grasping. Here's the results—a handful of good bullets. You can see wrinkles on a few noses due to the low alloy & mold temperatures, but these are 75 yard max hunting bullets, not target bullets. If you want perfect bullets, either cast at home or build up the fire and make more heat. More smoke, too. With an aluminum mold I had a pile of good bullets in maybe 30 minutes. An iron mold would have taken an hour just to get to a good casting temperature, especially over a campfire. Look at the meplats on those Ranch Dog bullets!

Sizing & lubing on a stump!

Here's the sizing & lubing equipment on the tailgate of my pickup. We see:

First, I had to snap the gas checks onto the base of the bullets. Some needed a little help from the whack it stick. When the gas check was on, I dropped the bullet/check in the zip sandwich bag. A squirt of Liquid Alox on the bullets inside the bag and some kneading of the bag, and the bullets had a coat of lube. Time for stump work with the whack it stick.

Here's a closer look. I always give my bullets two coats of Lee Liquid Alox—and never have barrel leading—so after a trip through the die they go back in the zip sandwich bag for another shot of lube. I let my stump-cast bullets dry overnight and loaded them the next day.

I used the back of my pocket knife blade to level the powder charges in the dipper. For case neck lube I put a drop of ATF on a rag. As I detailed the use of the Lee Classic Loader in my 2003 article and there's more instructions on the Lee web site, I won't repeat those steps here. I'll just say you better get a Classic Loader while Lee still makes and sells them. At about $30 it would be an indispensable tool if a worst case Y2K scenario came around.

Here we see a campfire-cast bullet in a stump-loaded round. I'm betting it and its mates are the only ones in America.

|