Copyright 2004 by Junior Doughty

Article #2 on 10" 7mm TCU

Back in 1982, I bought this Thompson-Center Contender in 7mm TCU for $400 in cash. It was in used/like new condition. With it came the 4X Burris scope, the hard case, the set of two dies and an extra barrel in 30-30. For almost a quarter century, this Contender has been one of my favorite firearms. Like my old Greenville, Mississippi, blues buddy T-Model Ford said, "I done been through a heap of knock-out, leg-broke, jaw-broke, fell-down troubles" and I still have my T-C 7mm TCU.

Back in 1982, I bought this Thompson-Center Contender in 7mm TCU for $400 in cash. It was in used/like new condition. With it came the 4X Burris scope, the hard case, the set of two dies and an extra barrel in 30-30. For almost a quarter century, this Contender has been one of my favorite firearms. Like my old Greenville, Mississippi, blues buddy T-Model Ford said, "I done been through a heap of knock-out, leg-broke, jaw-broke, fell-down troubles" and I still have my T-C 7mm TCU. T-C discontinued the 7mm TCU chambering several years ago and replaced it with the hotter 7x30 Waters. As a result, you can find used 7mm TCU barrels in gun shops and shows for around $100 ($150 in 2011) whereas a new 7x30 Waters barrel costs around $250. I'd rather have a 7mm TCU. The cartridge is easy to reload and fun to shoot. It's also super accurate and plenty powerful enough for 100 to 150 yard deer hunting. But its forte is plain ol' plinking. The moderate recoil allows for extended shooting sessions, and the accuracy will soon have you moving your targets further downrange to prevent boredom. I shoot clay pigeons placed against the dirt bank behind my 150 yard target. I've busted 5 for 5 many times.

My 30-30 WW case average usable case capacity = 2.38 cc. The 7mm TCU is a very efficient round as the table below shows. Using the data for a 120 gr jacketed bullet, I averaged all loads for 7mm TCU and 7x30 Waters listed in the pistol section of Hodgdon's 2004 Manual. I based the recoil figures on a gun weight of 4 lbs.

I don't know about you, but I wouldn't want to shoot a 7x30 Waters pistol all afternoon.

Reloading the 7mm TCUAll loads mentioned used CCI 400 primers and R-P cases trimmed and outside neck turned for uniformity on a Forster tool. An RCBS Uniflow Powder Measure threw the powder for all loads.You must fireform the cases from necked-up 223 Rem cases. That sounds like a lot of trouble, but trust me—it's easy. Just liberally lube the inside of 223 Rem case necks and full-length resize them in any 7mm TCU full-length resize die. The expander button/ball of the die will have a gentle taper designed to ease the expansion. I started with 200 new R-P 223 Rem cases, and, if memory serves, I ruined only one case during the necking-up process. By the way, I still use over 120 of those original cases, and they have been reloaded dozens of times over the past 20-something years. I don't remember ever getting a split neck. Most of the ruined cases had crushed necks due to misaligned bullets in the seating process. In other words, operator trouble. To fire form, you load as normal and shoot. I couldn't tell any difference in accuracy between those first fire formed loads and subsequent loads—all shot great. From left to right, here's the dies I use:

I dropped these bullets into the breech and let them stop against the lands. Then I measured the distances from their bases to the face of the breech. Here we see them in their approximate on-the-lands position relative to the case. Notice the inability to seat the 100 gr and 120 gr jacketed bullets even close to the lands. Notice the near perfect fit of the RCBS 7mm-145-SIL and the Hornady 154 gr SP. With those bullets seated so their base is level with the neck/shoulder junction, their noses touch or almost touch the lands.

I dropped these bullets into the breech and let them stop against the lands. Then I measured the distances from their bases to the face of the breech. Here we see them in their approximate on-the-lands position relative to the case. Notice the inability to seat the 100 gr and 120 gr jacketed bullets even close to the lands. Notice the near perfect fit of the RCBS 7mm-145-SIL and the Hornady 154 gr SP. With those bullets seated so their base is level with the neck/shoulder junction, their noses touch or almost touch the lands.

According to Hodgdon, it works best with medium burning powders such as H335, H322, H4895, and BL-C(2). I use Varget, which is a little slower. I asked "Help" at Hodgdon why they didn't show Varget loads for 7mm TCU as I got such good results. They answered: "The reason we do not show these loads is that they are not good loads. The pressures are too low and Varget has a burn speed unsuited to this cartridge." Regardless of what Help said, I plan to continue using Varget because:

Here we see cases filled nearly full with 28.5 grs Varget and ready for a seated 120 gr Sierra SP. As you saw from the to-the-lands picture above, the 120 gr bullet is seated just deep enough to stay in the case. The resulting load is slightly compressed, i.e., probably a 101% loading density. In other words, the 120 gr bullet is seated just deep enough so that I can shake the loaded round and the powder doesn't rattle. Here we see cases filled nearly full with 28.5 grs Varget and ready for a seated 120 gr Sierra SP. As you saw from the to-the-lands picture above, the 120 gr bullet is seated just deep enough to stay in the case. The resulting load is slightly compressed, i.e., probably a 101% loading density. In other words, the 120 gr bullet is seated just deep enough so that I can shake the loaded round and the powder doesn't rattle.Muzzle velocity of the 120 gr bullet + 28.5 grs Varget = 2005 fps. For the 154 gr SP, I use 25.5 grs Varget which fills the case to the neck/shoulder junction, i.e., a 100% loading density with the bullet seated to the same neck/shoulder junction. Muzzle velocity of the 154 gr bullet + 25.5 grs Varget = 1767 fps.

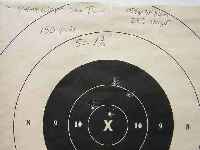

Shooting the 7mm TCU Here's a 100 yard, 1/2", 3 shot group, shot almost exactly 22 years before this writing. It used the Sierra 120 gr SP and a little too much H322, which is why I covered the amount. This group shows the potential of H322 and lighter bullets. Here's a 100 yard, 1/2", 3 shot group, shot almost exactly 22 years before this writing. It used the Sierra 120 gr SP and a little too much H322, which is why I covered the amount. This group shows the potential of H322 and lighter bullets. Muzzle velocity was 2100+ fps.

Muzzle velocity was 2005 fps.

The ruler and loaded round are for scale.

Muzzle velocity = 1767 fps.

Impact velocity of this load at 150 yards = 1545 fps. It blows a perfectly symmetrical 8" deep and 4" diameter hole in my dirt bank. I would have no qualms about shooting deer with this round to 150 yards. Zeroed for clay pigeons at 150 yards, it's 3" high at 100 yards. As one click on my 4x scope moves the crosshairs 1/2" at 100 yards, I'll go down 3 clicks and not worry about range out to 150 yards max if I decide to hunt with this round. The crosshairs of my Burris 4x hunting scope are about 3/4" wide at 150 yards; thus the gap between the black rectangles. I try to center the cosshairs as best I can, then squeeze the trigger.

5 shots @ 150 yards = 1 9/16" → 5 shots @ 150 yards = 2 1/8"; 4 = 9/16" → I had 2 sets of bullets in my loading/shooting block when I shot this group. For one set, with red marked noses, the bullets were seated with a standard seating die. For the other set, with unmarked noses, the bullets were seated to a different depth and with a micrometer seating die. So I'm happily shooting the group you see here and using the unmarked bullets. As I start to chamber round #5, the last round, I noticed that it had a red marked nose. Ah, heck, I said to myself. That ain't gonna make much difference. When I looked at the group and that $@#$%^& flyer, I almost cried.

Cast bullets I've had less than great success with cast bullets in my T-C 7mm TCU pistol. I've used the RCBS-145-SIL, the RCBS-168-SP, a Lyman 150 gr Loverin design, and even a custom nose pour Hoch mold I designed and on which I spent lots of 1982 dollars. Best results were with the RCBS-145-SIL.

I've had less than great success with cast bullets in my T-C 7mm TCU pistol. I've used the RCBS-145-SIL, the RCBS-168-SP, a Lyman 150 gr Loverin design, and even a custom nose pour Hoch mold I designed and on which I spent lots of 1982 dollars. Best results were with the RCBS-145-SIL. Here's a recent 10 shot, 100 yard group of 3 7/8" using the 145-SIL and 25.5 grs Varget. Gas checked, wheelweight alloy bullets were sized .285" and lubed with NRA formula Alox. Notice that 8 of the 10 bullets went in 2 1/4". Muzzle velocity = 1800 fps. To be fair, this 2004 group was shot with bullets cast circa 1982. I've learned a lot about casting and sorting bullets since then. Newly cast and sorted bullets plus a slightly faster powder such as H4895 might be the key to 2" or so 5 shot, 100 yard cast bullet groups in my 7mm TCU. A bore rider bullet about .0005" to .001" bigger than the bore might help too. I'll have to work on cast bullets again when I run low on my stash of 1,800 or so jacketed 154 gr SP blem bullets. In the meantime, if you're looking for a new-to-you T-C Contender barrel, don't overlook the 7mm TCU barrels discarded by the boys with handcannon fever.

|