Page 3

(Here we go again.)

Copyright 2005 by Junior Doughty Page 1 Page 2 Page 4

Click thumbnails for full size photos

|

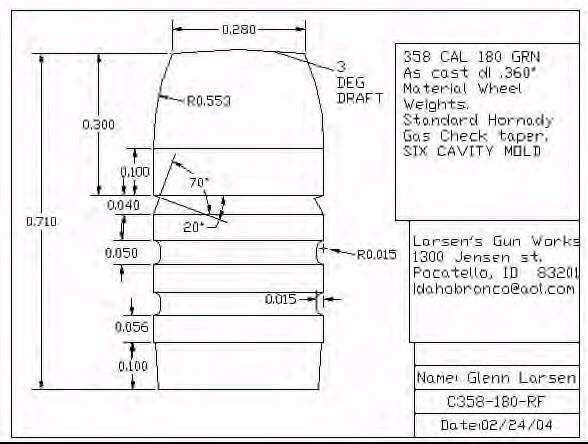

It was bound to happen. Along came a bigger and better cast bullet for my little Rossi Model 92 Winchester clone. The guys on the Castboolits Forum put together a group buy on a Lee 6-cavity C358-180-RF mold. Looked to me like a 180 gr cast bullet for 357 mag would work better on hogs and deer than the 165 gr bullet I was using, especially if I could push the 180 gr bullet to 1700 fps or so with Hodgdon's Lil'Gun. I sent off a $56 check, and the mold arrived about 8 weeks later. Below, see the bullet design. I really liked the looks of the huge meplat. It would hit like a sledgehammer.

With a micrometer I measured a dozen or more bullets at a point just above the crimping groove and opposite the seam. All measured exactly .3600". That's amazing uniformity from a 6-cavity mold.

It was time to load a test round and run it over the Chrony. First thing, I used the water method and measured the usable case capacity. Seating a trimmed case mouth even with the center of a bullet's crimping groove, the usable case capacity measured 1.09cc. The Cartridge Over All Length, COAL, measured 1.600". I do not have a laboratory. That usable case capacity figure could be off by 5 %. Use as a comparative reference only! With my jug of Lil'Gun's calculated VMD of .0683, a loading density of about 100% would weigh about 16 grs. That tickled me as I knew of guys getting 1800 fps with 180 gr jacketed bullets in 357 mag rifle using 15 to 16 grs of Lil'Gun. In addition, 100% loading density meant maximum efficiency, i.e., better potential for good accuracy. NOTE: The following loads are safe in my rifle only and with my components only. Do not use in a pistol. Do not use mag primers! A load perfectly safe in my rifle and with my components might swell your rifle's chamber—or worse!

My components were:

I charged a case with 15 grs of Lil'Gun and seated a bullet mid-way of its crimping groove, using a very light crimp. I pushed it through the loading gate and into the magazine, then worked the lever to ram it home. Huh? It was jammed!

The too-long round chambered easily by hand. I fired it over the Chrony and read a satisfying 1711 fps. The case ejected easily. The primer wasn't even partially flattened. Heck, I considered, I could hunt with a 190 gr round in the chamber and fill the magazine with 165 gr rounds. But round #2, a 165 gr round, would have a different Point Of Impact. I needed to make the 190 gr round feed. I posed my problem to the guys on a forum. Steve from www.stevesgunz.com graciously offered his advice—for free! If I didn't want to lower my case capacity, Steve said, I could, first, grind a little ramp at the lower entrance of the chamber, or, second, grind a little off the cartridge guides.

BEWARE, Steve warned. If I took too much off the entrance to the chamber

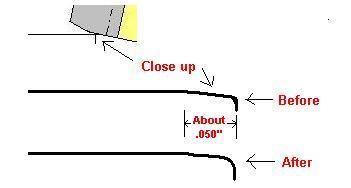

Using my Dremel® tool and a low speed setting, I very carefully deepened the ramp in just the bottom edge of the chamber. Basically, all I did was dull the chamber's edge, as the close up shows. I loaded a bullet into an old W-W case, seated it to a COAL of 1.600", and used it as a test round as I slowly ground off the edge of the chamber. Finally, the test round slipped easily past the guides and up and into the chamber. Smiling smugly at my own ingenuity, I'm sure, I loaded a new R-P case with 15.3 grs of Lil'Gun and seated a bullet to a COAL of 1.600". I slid the round into the magazine, then briskly worked the lever to feed the round into the chamber. What? The #$%^%&*^$ jammed! No way was I doing any more grinding on the chamber entrance. No way was I taking the rifle apart and grinding on the guides. I considered sending the rifle and a couple of test rounds to Steve. While I wondered about costs and worried about losing my beloved Rossi in shipping, I hand chambered the 15.3 gr Lil'Gun round and sent it over the Chrony—it read 1750 fps. Again, easy extraction and round primers. Man, I told myself, I have got to make this sucker feed. The velocity is perfect. Why in heck would one round feed and an identical-looking round not feed? The answer came via a micrometer. The rim on the old W-W case measured .002" smaller in diameter than the rim on the new R-P case. The larger rim put the case at a larger entrance angle. Plus, the ogive of the test round was a little worn down after being fed into the chamber at least 50 times. Even if the R-P case fed, I realized, it was on the borderline of not feeding. Nothing to do but work on seating depth and, therefore, lower the COAL. I decided to use an R-P case and lower the COAL a few thousandths at a time until the round fed. So I loaded a bullet into a primerless, powderless R-P case and seated it for a COAL of 1.600" and with the case mouth centered in the bullet's crimping groove. I then used a Lee Factory Crimp Die and gave the case mouth a medium crimp. Screwing the seater die stem down a little at a time and gently trying the case for feeding each time, the round finally fed at a COAL of 1.575".

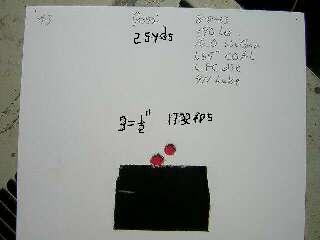

But even though a COAL of 1.575" fed, it was on the borderline of not feeding. It needed a little feeding insurance. About .025" in insurance, I figured. I charged a primed R-P case with 15.0 grs Lil'Gun, and I then seated a 190 gr bullet in it to a COAL of 1.550". The case mouth now resting above the bullet's crimping groove, I forced a crimp into the ogive with a Lee Factory Crimp Die. It's the round on the right in the photo above. Look at the full size version of the photo, and you can see the crimping groove forced into the bullet by the Lee Factory Crimp Die. I loaded 3, 1.550" COAL rounds with 15.0 grs Lil'Gun and ran all 3 over the Chrony for both 25 yard group and statistics. With the bullets now seated lower in the cases the usable case capacity was less, so I expected different Chrony data and I got it. Before, the loading density was about 93 %. Now, it would approach 100 % or even a little more. I increased the Lil'Gun charge in .5 gr increments and shot 2 more groups. See the data below. First, let us review the old (one shot only) data with a COAL of 1.600":

Although the 16.0 grs of Lil'Gun rounds @ 1732 fps showed no signs of high pressure, I considered it maximum and stopped there. Remember my warning: It could be above maximum in your rifle! On the right, see the 16.0 grs Lil'Gun group mentioned above. It's the best 3 shot group ever fired in my Rossi 357 mag rifle. Even with their great accuracy I will save my remaining 190 gr bullets for hunting season. Besides, they're a little big for shooting beer cans, don't you think?

Below, see the exterior ballistic results of both loads zeroed at 75 yards:

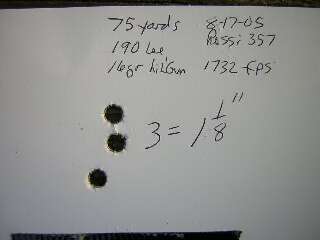

Speaking of 75 yards, check out the 75 yard group on the right. I shot it while playing with zero. The full size photo shows the group larger than actual size! During my hassle over the C358-180-RF feeding problem, I almost put the mold up for sale to recoup my $56. Now, it ain't for sale at $150.

|

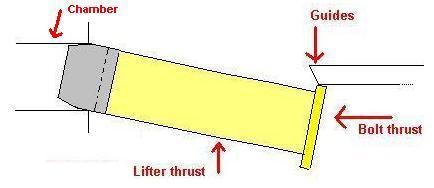

As this graphic shows, the round jammed just after entering the chamber. It was in a bind in 3 places:

As this graphic shows, the round jammed just after entering the chamber. It was in a bind in 3 places:

This graphic shows a close up of the chamber entrance and depicts what I did. The chamber entrance already contained a ramp—a 1 or 2 degree funnel-like slope made to facilitate feeding. As the graphic shows, the funnel-like slope extended about .050" into the chamber.

This graphic shows a close up of the chamber entrance and depicts what I did. The chamber entrance already contained a ramp—a 1 or 2 degree funnel-like slope made to facilitate feeding. As the graphic shows, the funnel-like slope extended about .050" into the chamber.