UPDATE

Copyright 2007 by Junior Doughty First article here.

|

I decided to reinforce the H Town Imports mount on my M38 Mosin-Nagant so I could clean the rifle without having to remove the scope. Due to the poor light gathering ability of the cheap scope you see here I replaced it with a 2.5 x 28 IER Leupold. Long story short, a nice buck entered a thicket just as the sun went behind a cloud. I didn't know the old scope had poor optics until that moment. The Leupold scope you see below cost 4 times what the rifle cost, but what good is money when you can't see a deer in dim light? So I had a double project—alter and reinforce a mount and replace a scope. I used Weaver "Low" mounts because the old mounts were (1) too high above the barrel; and (2) had metric screws. I hacksawed off the excess metal at the front and rear of the scout scope mount. The rear Weaver ring looks like it hangs off the edge of the mount, but that's mainly due to the camera angle. The ring is almost even with the back of the mount. Open the full size photo and look beneath the OL in LEUPOLD, and you'll see the head of a 6-48 Fillister screw. It's clearanced through the mount and screws into the military rear sight bracket via a hole I drilled and tapped. The screw keeps the scope & mount from twisting counterclockwise when the rifle recoils. I shouldn't tell this on myself, but I intended to put a 6-48 reinforcement screw on the other side of the mount. But I forgot about the locking screw on the other side. The drill bit hit the little screw, boogered it severely, and came out the side of the mount. Not only did I screw that screw up, I didn't plan for the angle of the military sight bracket when I drilled the hole on this side. I should have used a center punch so the bit would start straight. I didn't. The bit hit the slope and bent to the right. I ended up with an oblong hole. Nothing to do but tap the misdrilled hole anyway. But never fear—help is near. Good ol' J & B Weld saved the day. I cleaned the oil from the tapped hole and filled it with J & B Weld. Then I installed the screw, letting the J & B Weld fill the gaps. So far, it's held through several full-bore loads. If it doesn't, look for another update. . . .

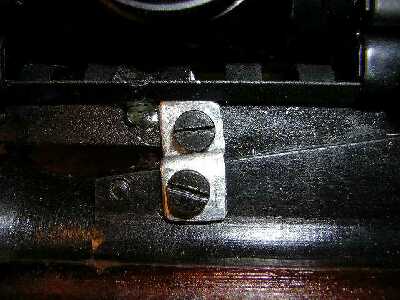

The homemade reinforcement bracket is attached with two Fillister screws, an 8-40 x 3/8" into the aluminum scout scope mount, top, and an 8-40 x 1/4" through the steel military sight mount, bottom. I think I can stop worrying about the scout scope mount shooting loose.

|