Copyright 2005 by Dennis Dezendorf

|

Since the original article on my Pedretti Sharps, I have been developing loads for that rifle. I quickly learned that the original sight on the rifle, a German silver blade, would not give me the sight picture I wanted in order to shoot the groups I thought the rifle was capable of shooting. During the late summer or fall of 2004 I purchased a Lyman 17 globe sight and installed it on the rifle. The globe sight may not be original or authentic, but it has been used by target riflemen to squeeze the best possible accuracy out of many rifles. The Lyman fit with my stated goals for the rifle:

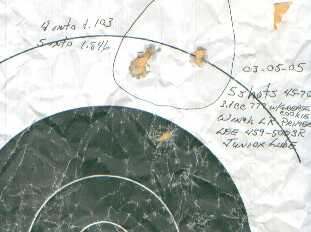

So, I spent the summer and fall of 2004 shooting BP substitutes in the rifle, learning the peccadilloes of the rifle and loading for it. I tried loads at random, searching for that magical combination of bullet, powder and loading technique that would give me the accuracy I was looking for. During the late winter of 2004 I decided I had been playing around long enough and that it was time to make the rifle shoot. I had been getting groups of 4" to 5" with a number of powders and bullet combinations and I was getting frustrated at the amount of lead I was sending downrange without any appreciable improvement. While a 4" group is good enough for deer hunting, I wanted something better. I have always liked pointed bullets and Lee makes one, the 459-500-3R, a pointed spitzer shape with a ballistic coefficient of .443. I bought a mold and loaded some of those bullets with various powders. Groups with this bullet were frustrating because I would get two shots touching and the rest of the shots in the string would open the group up to the 3" range.

Then, one day on a trip to Wal-Mart With those cautions in mind, I realized that I didn't know how much of the available powder space was taken up by the bullet, and how much was available for powder. Time to do a little experiment.

Lets talk a little about bullet prep. The Lee 459-500-3R bullet is a plain based lead bullet with three lube grooves. To help the bullet fly properly and to reduce leading I needed to lube the bullet. Because I am a frugal shooter, I wanted the loading process to be as simple and economical as possible. In short, I wanted homemade lube. I don't own a lubrisizer, but I do have a Lee .457 sizer. That little device uses a standard press and one die to press the bullet through to a uniform size. I knew from past work that my rifle liked bullets sized to .457 and didn't see any reason that the 3R bullet would be any different.

Bullet prep complete, I was ready to load some cartridges. I remembered that my brass would allow me to use 3.1 ccs of Hodgdon 777 as a starting load, giving me 100% loading density with no air space under the bullet. Previous experience with my rifle showed that it shot best with a grease cookie, so I poured a little Junior Lube on a sheet of waxed paper and let it harden to use as cookie materiel. I loaded five rounds with that combination; 3.1 ccs of 777, a grease cookie and a Lee 459-500-3R bullet. I marked the primers of the loaded rounds with a felt tipped pen so that I could keep remember which load was which. When developing loads, I often use felt tipped markers on the primers. I generally use four colors; black, red, blue, and green. When building variations of a single load I put a different color on each primer. Then I make a little cheat-sheet that I can place in the box with the cartridges. When I get to the range a week or month later I have that little cheat sheet that details the specifics of each load. I find this little technique useful. It saves marking the brass, and when I punch the primer out to reload the brass I can mark the new primer in any way I need to mark it. Next, I loaded five rounds each with 3.4 ccs, 3.7 ccs, and 4.0 ccs of Hodgdon 777. The primers got appropriate colors so that I could keep the various cartridges separate when I took them to the range. Range day dawned overcast but still. Perfect conditions for group shooting. I loaded the rifle, bullets and paraphernalia into the truck and headed toward the range. I picked up my son on the way, as he wanted to shoot his deer rifle.

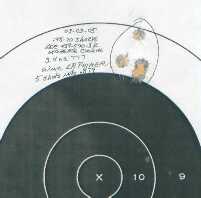

The target shows the same tendency that the others have shown, with a cluster in one hole, and a couple of flyers. The difference is that the flyers are a lot closer to the cluster.

That's true, but I only fired five shots at that target, and I am including it here to show you one of the little weird things that can happen when you shoot at a public range. There were a number of people shooting that day. They were shooting rifles and pistols at various ranges, from 5 yards to 100 yards. All my targets were shot at 100 yards. Somehow an errant bullet came sailing downrange and pierced my target. I can't tell you which hole is from someone else's gun, but there you have it. Didn't really matter. I found my load for my Sharps. The 3.4 cc load turned in good accuracy. All I have to do is regulate the sights to that load and I know that when I miss, it is my fault and mine alone. I know that my rifle is capable of the best accuracy I can wring out of it. Now, all I have to do is find a 500 yard gong.

|